Ana amfani da kwayoyi na hex tare da kusoshi da sukurori don haɗawa da ƙara ƙara kayan aikin injiniya. Hexagonal nuts of different types and grades are suitable for different occasions to meet different precision and surface treatment requirements. Ana amfani da shi sosai, tare da ƙarfi mai ƙarfi, dacewa da lokatai masu buƙatar babban wurin aiki. "

| Sunan samfur | DIN934 Hex Nut |

| Kayan abu | Carbon karfe, bakin karfe |

| Ƙarshen Sama | Zinc fari shuɗi, Baƙar fata, Zinc mai launin rawaya, Launi na halitta, Ƙarfafawa, Farin zinc |

| Launi | Blue fari, Baƙar fata, Yellow, Fari |

| Adadin Lamba | DIN934 |

| Daraja | 4 6 8 | 8| 10 12 A2-70 A4-70 |

| Diamita | M2 M2.5 M2.6 M3 M3.5 M4 M5 M6 M7 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 M33 M36 M39 M42 |

| Sigar zaren | Zare mara kyau, Zaren Matsakaici, Zare mai kyau, Zare mai kyau sosai, Zaren baya, Zare mai kyau |

| Wurin asali | Hebei, China |

| Alamar | Muyi |

| Kunshi | Akwatin + kwali kwali + pallet |

| Ana iya keɓance samfurin | |

| Ana amfani da kwayoyi na hex tare da kusoshi da sukurori don haɗawa da ƙara ƙara kayan aikin injiniya. Hexagonal nuts of different types and grades are suitable for different occasions to meet different precision and surface treatment requirements. Ana amfani da shi sosai, tare da ƙarfi mai ƙarfi, dacewa da lokatai masu buƙatar babban wurin aiki. " | |

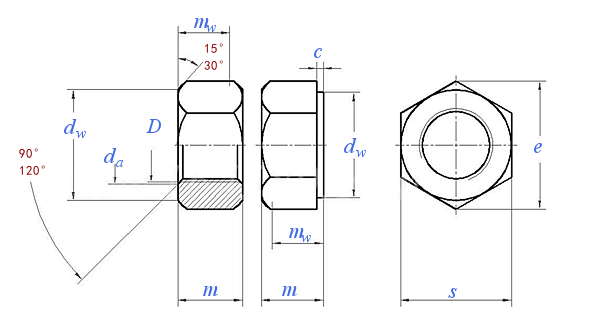

| Bayanin Zare D | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | M56 | |

| P | jagoran jirgin | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 |

| c | max | 0.2 | 0.2 | 0.3 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

| da | max | 1.84 | 2.3 | 2.9 | 3.45 | 4 | 4.6 | 5.75 | 6.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 23.7 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | 56.2 | 60.5 |

| min | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | 52 | 56 | |

| dw | min | 2.4 | 3.1 | 4.1 | 4.6 | 5 | 5.9 | 6.9 | 8.9 | 11.6 | 14.6 | 16.6 | 19.6 | 22.5 | 24.9 | 31.4 | 33.3 | 38 | 42.8 | 46.6 | 51.1 | 55.9 | 60 | 64.7 | 69.5 | 74.2 | 78.7 |

| e | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 29.56 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 |

| m | max | 1.3 | 1.6 | 2 | 2.4 | 2.8 | 3.2 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 | 12.8 | 14.8 | 15.8 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 | 33.4 | 34 | 36 | 38 | 42 | 45 |

| min | 1.05 | 1.35 | 1.75 | 2.15 | 2.55 | 2.9 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 18.1 | 20.2 | 22.5 | 24.3 | 27.4 | 29.4 | 31.8 | 32.4 | 34.4 | 36.4 | 40.4 | 43.4 | |

| mw | min | 0.8 | 1.1 | 1.4 | 1.7 | 2 | 2.3 | 3.5 | 3.9 | 5.2 | 6.4 | 8.3 | 9.7 | 11.3 | 12.1 | 14.5 | 16.2 | 18 | 19.4 | 21.9 | 23.5 | 25.4 | 25.9 | 27.5 | 29.1 | 32.3 | 34.7 |

| s | max=matsayi | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 |

| min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | |