Hexagonal kulle bakin ciki kwayoyi ana kuma amfani da ko'ina a cikin samarwa da kuma masana'antu tafiyar matakai na daban-daban inji kayan aiki, kida, iyali kayan, da dai sauransu

| Sunan samfur | DIN985 Hex Lock Nut tare da shuɗi |

| Kayan abu | Karfe Karfe, Bakin Karfe |

| Ƙarshen Sama | Yellow tutiya, Blue farin tutiya, Original launi, White tutiya, Decolourize, Dacromet |

| Launi | Rawaya, Farin shuɗi, Fari |

| Adadin Lamba | DIN985 |

| Daraja | 4 8 10 A2-70 |

| Diamita | M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 M33 M36 M39 M45 M48 |

| Sigar zaren | M zaren |

| Wurin asali | Hebei, China |

| Alamar | Muyi |

| Kunshi | Akwatin + kwali kwali + pallet |

| Ana iya keɓance samfurin | |

| 1. Mechanical masana'antu: Hexagonal kulle bakin ciki kwayoyi da aka yafi amfani da su haɗa da gyara daban-daban inji aka gyara, kamar sukurori, flanges, bearings, da camshafts, don tabbatar da al'ada aiki na inji. 2. Masana'antar kera motoci: A cikin tsarin masana'antar kera motoci, ana amfani da ƙwaya masu kulle-kulle na hexagonal don haɗawa da amintattun abubuwan kera motoci daban-daban kamar injuna, axles, da dakatarwa don tabbatar da aminci da kwanciyar hankali na abin hawa. 3. Ginin filin: Hexagonal kulle bakin ciki kwayoyi ana amfani da ko'ina a cikin taro na karfe Tsarin, kamar gadoji, masana'antu, da dai sauransu Su ne nauyi da kuma da kyau anti loosening Properties, wanda zai iya tabbatar da kwanciyar hankali da aminci na karfe Tsarin lokacin amfani. 4. Na’urorin lantarki: A fagen kera kayayyakin lantarki, kamar wayar hannu, kwamfuta, da sauransu, ana amfani da goro mai kulle siriri guda shida don gyarawa da haɗa abubuwa daban-daban, kamar batura, uwa-uba, nuni da sauransu, don adana sarari da rage nauyi. 5. Ado na gida: A fagen kayan ado na gida, ana amfani da ƙwaya masu kulle siriri guda shida a cikin haɗar kayan daki, kayan wasan yara da sauran kayayyaki, waɗanda ba kawai za su iya taka rawar gyarawa ba amma har ma da kula da tsaftataccen yanayi. 6. Gabaɗaya filin: Hexagonal kulle bakin ciki kwayoyi ana kuma amfani da ko'ina a cikin samarwa da kuma masana'antu tafiyar matakai na daban-daban inji kayan aiki, kida, iyali kayan, da dai sauransu. | |

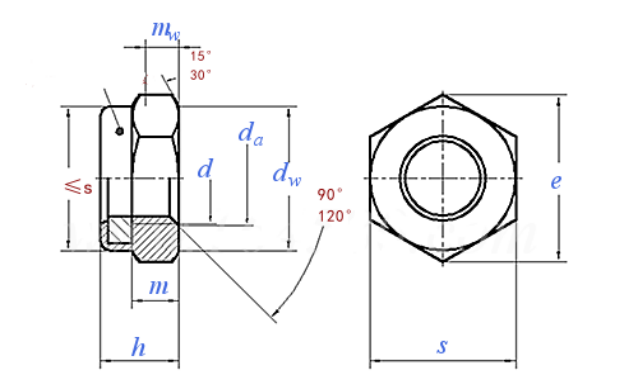

| Bayanin Zare D | M3 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | ||

| P | jagoran jirgin | M zaren | 0.5 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 |

| Zare mai kyau1 | / | / | / | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | ||

| Zare mai kyau2 | / | / | / | / | / | / | 1.25 | 1.25 | / | / | 1.5 | 1.5 | 1.5 | / | / | / | / | / | / | / | / | / | ||

| da | min | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | |

| max | 3.45 | 4.6 | 5.75 | 6.75 | 7.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 21.6 | 23.7 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | ||

| dw | min | 4.6 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | 24.9 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.6 | 51.1 | 55.9 | 60.6 | 64.7 | 69.4 | |

| e | min | 6.01 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 72.09 | 76.95 | 82.6 | |

| h | max=matsayi | 4 | 5 | 5 | 6 | 7.5 | 8 | 10 | 12 | 14 | 16 | 18.5 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | |

| min | 3.7 | 4.7 | 4.7 | 5.7 | 7.14 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 17.66 | 18.7 | 20.7 | 22.7 | 25.7 | 28.7 | 31.4 | 34.4 | 37.4 | 40.4 | 43.4 | 46.4 | ||

| m | min | 2.4 | 2.9 | 3.2 | 4 | 4.7 | 5.5 | 6.5 | 8 | 9.5 | 10.5 | 13 | 14 | 15 | 15 | 17 | 19 | 22 | 25 | 27 | 29 | 32 | 36 | |

| mw | min | 1.65 | 2.2 | 2.75 | 3.3 | 3.85 | 4.4 | 5.5 | 6.6 | 7.7 | 8.8 | 9.9 | 11 | 12.2 | 13.2 | 14.8 | 16.5 | 18.2 | 19.8 | 21.5 | 23.1 | 24.8 | 26.5 | |

| s | max=matsayi | 5.5 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | |

| min | 5.32 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.8 | 68.1 | 73.1 | ||

| 1000 inji mai kwakwalwa / nauyi KG | 0.5 | 1 | 1.4 | 2.4 | 3 | 5.1 | 10.6 | 17.2 | 26 | 34 | 45 | 65 | 75 | 100 | 162 | 212 | 317 | 415 | 499 | 628 | 771 | 998 | ||