Perawatan lumahing: Kanggo nambah resistance karat, bolt peserta bisa nggunakake macem-macem cara perawatan lumahing, kayata hot-dip galvanizing, infiltrasi plating, plating putih, werna plating, etc. Kajaba iku, dhuwur-kekuatan bolt biasane dianggep karo nggodhok ireng biru kanggo nambah tampilan lan resistance karat.

| Jeneng produk | Bolts Mripat DIN444 |

| Bahan | Baja karbon, Baja tahan karat |

| Lumahing Rampung | Seng kuning, Blackened, Seng biru lan putih, Bleached |

| warna | Kuning, Ireng, Biru Putih, Putih |

| Nomer Standar | DIN444 |

| sasmita | 4 8 10 A2-70 |

| Dhiameter | M5 M6 M8 M10 M12 M16 M20 M24 M30 M36 M39 |

| Bentuk utas | Utas kasar, Utas alus |

| Panggonan asal | Hebei, China |

| Merk | Muyi |

| Pack | Box + kardus + pallet |

| Produk bisa disesuaikan | |

| 1. Perawatan lumahing: Kanggo nambah resistance karat, bolt peserta bisa nggunakake macem-macem cara perawatan lumahing, kayata hot-dip galvanizing, infiltrasi plating, plating putih, werna plating, etc. Kajaba iku, dhuwur-kekuwatan bolt biasane dianggep karo nggodhok ireng biru kanggo nambah tampilan lan resistance karat. Masalah 2.Sealing: Ing klep lan peralatan liyane, kinerja sealing bolt mripat iku penting banget. Sembarang panyegelan sing ora apik bisa nyebabake katup bocor, netes, lan liya-liyane, saengga kualitas bolt mripat kudu dipastiake kanggo njamin keamanan lan linuwih sistem sakabèhé. 3. Aplikasi Wide: Amarga nggunakake bolt mripat trep lan cepet, lan digunakake karo nut cocog kanggo nyambungake lan ngencengi, wis sawetara saka sudhut aplikasi. Bolts mripat digunakake digunakake ing katup suhu rendah lan tekanan dhuwur, pipa tekanan, teknik cairan, peralatan pengeboran minyak, peralatan lapangan minyak lan lapangan liyane. Asring digunakake ing acara utawa piranti kanggo disassembly lan sambungan, kayata industri katup, sepedha lempitan, lan gerbong bayi. | |

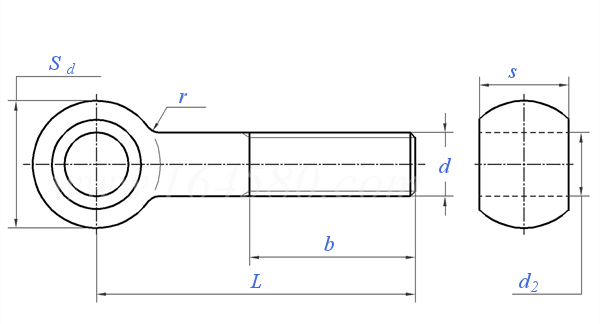

| Spesifikasi Thread d | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | (M27) | ||

| P | Pitch | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | 3 | |

| b | L≤125 | 16 | 18 | 22 | 26 | 30 | 38 | 46 | 54 | 60 | |

| 125<L≤200 | - | - | 28 | 32 | 36 | 44 | 52 | 60 | 66 | ||

| L>200 | - | - | - | - | 49 | 57 | 65 | 73 | 79 | ||

| d2 | min= nominal | 5 | 6 | 8 | 10 | 12 | 16 | 18 | 22 | 24 ② | |

| maks | 5.03 | 6.03 | 8.036 | 10.036 | 12.043 | 16.043 | 18.043 | 22.052 | 24.052 | ||

| Sd | maks | 12 | 14 | 18 | 20 | 25 | 32 | 40 | 45 | 50 | |

| Tipe A | min | 10.9 | 12.9 | 16.9 | 18.7 | 23.7 | 30.4 | 38.4 | 43.4 | 48.4 | |

| Tipe B lan C | min | 11.57 | 13.57 | 17.57 | 19.48 | 24.48 | 31.38 | 39.38 | 44.38 | 49.38 | |

| r | Nominal | 2.5 | 4 | 4 | 4 | 6 | 6 | 6 | 10 | 10 | |

| maks | 3.75 | 6 | 6 | 6 | 9 | 9 | 9 | 15 | 15 | ||

| min | 1.875 | 3 | 3 | 3 | 4.5 | 4.5 | 4.5 | 7.5 | 7.5 | ||

| e | Tipe A | maks | 8 | 9 | 11 | 14 | 17 | 19 | 24 | 28 | 30 |

| min | 7.52 | 8.52 | 10.3 | 13.3 | 16.3 | 18.16 | 23.16 | 27.16 | 29.16 | ||

| Tipe B lan C | maks | 6 | 7 | 9 | 12 | 14 | 17 | 22 | 25 | 27 | |

| min | 5.88 | 6.85 | 8.85 | 11.82 | 13.82 | 16.82 | 21.79 | 24.79 | 26.79 | ||

| Spesifikasi Thread D | (M27) | M30 | M30 | (M33) | M36 | M36 | (M39) | (M39) | ||

| P | Pitch | 3 | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | 4 | |

| b | L≤125 | 60 | 66 | 66 | - | - | - | - | - | |

| 125<L≤200 | 66 | 72 | 72 | 78 | 84 | 84 | 90 | 90 | ||

| L>200 | 79 | 85 | 85 | 91 | 97 | 97 | 103 | 103 | ||

| d2 | min= nominal | 25 | 27 ② | 28 | 30 | 32 | 33 ② | 35 | 36 ② | |

| maks | 25.052 | 27.052 | 28.052 | 30.052 | 32.062 | 33.062 | 35.062 | 36.062 | ||

| Sd | maks | 50 | 55 | 55 | 60 | 65 | 65 | 70 | 70 | |

| Tipe A | min | 48.4 | 53.1 | 53.1 | 58.1 | 63.1 | 63.1 | 68.1 | 68.1 | |

| Tipe B lan C | min | 49.38 | 54.26 | 54.26 | 59.26 | 64.26 | 64.26 | 69.26 | 69.26 | |

| r | Nominal | 10 | 10 | 10 | 16 | 16 | 16 | 16 | 16 | |

| maks | 15 | 15 | 15 | 22.4 | 22.4 | 22.4 | 22.4 | 22.4 | ||

| min | 7.5 | 7.5 | 7.5 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | ||

| e | Tipe A | maks | 30 | 34 | 34 | 38 | 41 | 41 | 46 | 46 |

| min | 29.16 | 33 | 33 | 37 | 40 | 40 | 45 | 45 | ||

| Tipe B lan C | maks | 27 | 30 | 30 | 34 | 38 | 38 | 41 | 41 | |

| min | 26.79 | 29.79 | 29.79 | 33.75 | 37.75 | 37.75 | 40.75 | 40.75 | ||