२०२५-०९-२०

धेरै औद्योगिक सेटिङहरूमा, सुरक्षित एन्करिंग आवश्यक छ। बोल्टहरू टगल गर्नुहोस् प्रायः छनोट गरिन्छ, तर तिनीहरूको आवेदन गलतफहमी हुन सक्छ, जसले सम्भावित क्षतिहरू निम्त्याउँछ। वास्तविक संसारको अनुभवबाट व्यावहारिक अन्तर्दृष्टिहरूमा डुबौं।

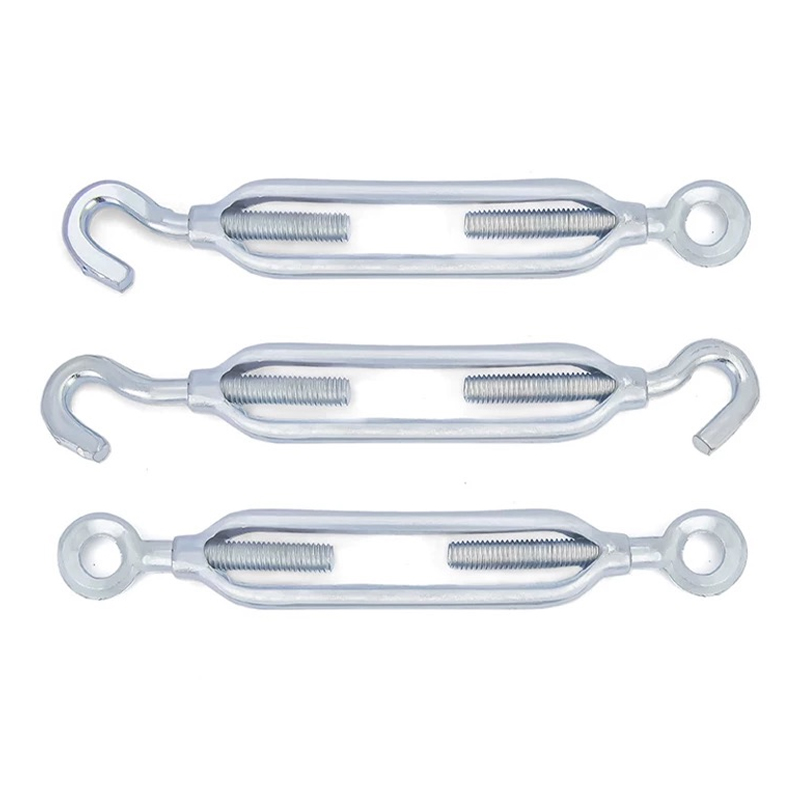

जब यो भारी भारहरू ह्यान्डल गर्ने कुरा आउँछ, टगल बोल्टहरूले भरपर्दो समाधान प्रदान गर्दछ। तिनीहरू विशेष गरी खाली पर्खालहरू र अन्य सामग्रीहरूको लागि डिजाइन गरिएका छन् जहाँ परम्परागत एङ्करहरू असफल हुन सक्छन्। तिनीहरूको अद्वितीय विशेषता भनेको वसन्त-भारित पखेटाहरू हुन्, जो पर्खालको पछाडि खोलिन्छन् र प्रभावकारी रूपमा लोड वितरण गर्न।

उदाहरणका लागि, भारी मेसिनरी वा ठूला फिक्स्चरहरू स्थापना गर्दा, बोल्टको सही साइज र यसलाई राखिएको प्वाल बुझ्न महत्त्वपूर्ण छ। ठूला आकारका प्वालहरूले अस्थिरता निम्त्याउन सक्छ, जबकि सानो आकारका प्वालहरूले पखेटाहरूलाई पूर्ण रूपमा तैनात हुनबाट रोक्न सक्छ। यो हो जहाँ धेरै पहिलो-टाइमरहरू यात्रा गर्छन्।

मेरो अनुभवमा, पखेटाका लागि सही सामग्री छनोट गर्नु पनि महत्त्वपूर्ण छ। उच्च आर्द्रता वा संक्षारक वातावरणमा, जस्ता-प्लेटेड स्टीलको सट्टा स्टेनलेस स्टीलको लागि छनौट गर्दा दीर्घकालीन गिरावट रोक्न सक्छ।

एउटा सामान्य त्रुटिले सबैलाई अनुमान गर्दैछ टगल बोल्टहरू समान रूपमा सिर्जना गरिन्छ। वास्तवमा, तपाईंले पर्खालको मोटाई र वस्तुको वजन दुवैलाई विचार गर्नुपर्छ। त्यसो गर्न असफल भएमा पर्खालको संरचनालाई कम-कसाउन वा अत्यधिक तनावको परिणाम हुन सक्छ।

जीर्ण पर्खाल भएका पुराना भवनहरूमा अर्को समस्या उत्पन्न हुन्छ। यहाँ, भित्ताको सब्सट्रेट कमजोर वा सम्झौता भएको खण्डमा पूर्ण रूपमा स्थापित टगल बोल्ट पनि तान्न सक्छ। सधैं पहिले पर्खाल अखण्डता मूल्याङ्कन; कहिलेकाहीँ, समाधान बलियो बोल्टको बारेमा होइन तर पर्खाल आफैलाई सुदृढ पार्ने बारे हो।

भर्खरै, हामीसँग एउटा परिदृश्य थियो जहाँ सबपार बोल्टहरू प्रयोग गरिन्थ्यो, जसले महँगो मेसिनको पतन निम्त्याउँछ। एक विस्तृत समीक्षाले अनुपयुक्त जंग प्रतिरोधको कारण पखेटा थकान प्रकट गर्यो। यसले उच्च गुणस्तरीय फास्टनरहरूमा विशेषज्ञता राख्ने Hebei Muyi Import & Export Trading Co., Ltd जस्ता प्रतिष्ठित आपूर्तिकर्ताहरूबाट सोर्सिङको महत्त्वलाई जोड दियो।

पहिलो नियम संग टगल बोल्टहरू स्थापना हतार छैन। उचित तयारीले परिणाम बनाउन वा तोड्न सक्छ। पर्खालको प्रकार र यसको पछाडि के छ भनेर बुझ्न सुरु गर्नुहोस्। खाली पर्खालहरू पछाडि, बिजुलीका लाइनहरू वा पाइपहरू नछोड्ने सुनिश्चित गर्नुहोस्।

सँधै निर्दिष्ट व्यासमा सही रूपमा पूर्व-ड्रिल प्वालहरू। औद्योगिक अनुप्रयोगहरूमा, ड्रिलिंग अघि निरीक्षणहरू महत्त्वपूर्ण छन्। एक बलियो क्ल्याम्प मेकानिज्म वा समर्थनले बोल्टको पखेटालाई मद्दत गर्दछ, एक पटक भित्र भरपर्दो खुल्ने प्रदान गर्दछ।

वजन क्षमता परीक्षण अर्को महत्त्वपूर्ण चरण हो। गणनामा मात्र भर पर्दैन; यसको सट्टा, वास्तविक परिस्थितिहरूमा सेटअपको स्थायित्व पुष्टि गर्न क्यालिब्रेट गरिएका परीक्षणहरू प्रयोग गर्नुहोस्।

अत्यधिक मेकानाइज्ड वातावरणमा, टगल बोल्टहरू जताततै हुन्छन् - कन्ट्रोल प्यानलहरू सुरक्षित गर्ने देखि छतमा टाँसिएको एकाइहरू सम्म। सामान्य परिदृश्यमा HVAC स्थापनाहरू समावेश हुन्छन् जहाँ टगल बोल्टहरूले खतरनाक ढल्नबाट जोगाउन भारी डक्टवर्क सुरक्षित गर्दछ।

हाम्रो सुविधामा एउटा उल्लेखनीय केस थियो जहाँ टगल बोल्टले दुई टन उपकरणहरूलाई समर्थन गर्ने निलम्बित प्लेटफर्म सुरक्षित गर्यो। सफलता चरम अवस्थामा बोल्टको क्षमता प्रमाणित गर्दै, पूर्ण लोड परीक्षण र उच्च-तन्य शक्ति सामग्री प्रयोग गरेर आयो।

यी उदाहरणहरूलाई प्रतिबिम्बित गर्दै, यो स्पष्ट छ कि सही प्राविधिक विशिष्टताहरू र शीर्ष-ग्रेड सामग्रीहरूको संयोजन - https://www.muyi-trading.com बाट भएका ब्रान्डहरूले सञ्चालनको सुरक्षा बनाउन वा तोड्न सक्छ।

पहिले छुएझैं, तपाईंको स्रोत टगल बोल्टहरू तिनीहरूको प्रदर्शनमा आधारभूत भूमिका खेल्छ। घटिया सामग्रीहरूले सुरुमा लागत बचत गर्न सक्छ, तर तिनीहरूले निम्त्याउने जोखिम यसको लायक छैन। Hebei Muyi Import & Export Trading Co., Ltd जस्ता अनुभवी प्रदायकहरूसँग साझेदारीले गुणस्तर मात्र होइन आवेदनमा विशेषज्ञ निर्देशन पनि सुनिश्चित गर्दछ।

थप रूपमा, भरपर्दो आपूर्तिकर्तासँग चलिरहेको सम्बन्धले अक्सर नयाँ उत्पादन विकास वा प्रगतिहरूमा बहुमूल्य अन्तर्दृष्टि ल्याउँछ जसले परिचालन दक्षता वा सुरक्षा बढाउन सक्छ।

अन्तमा, औद्योगिक सेटिङहरूमा टगल बोल्टहरूले तिनीहरूको जटिलता र सम्भावित परिणामहरूको लागि सम्मानको माग गर्दछ। उत्कृष्ट अभ्यासहरू सुनिश्चित गर्ने, गुणस्तरीय सामग्रीहरू उपलब्ध गराउने, र वातावरणमा गहिरो नजर राख्ने जहाँ तिनीहरू तैनात छन् तिनीहरूको वास्तविक क्षमता महसुस गर्ने सबै भाग हुन्।

कृपया तपाईंको इमेल ठेगाना प्रविष्ट गर्नुहोस् र हामी तपाईंको इमेलको जवाफ दिनेछौं।