1.Bolts za hexagonal hutumiwa sana ndani na nje. Maombi ya nje ni zaidi ya ujenzi wa mitambo, madaraja na barabara, na vifaa vya nguvu; maombi ya ndani zaidi ni ya vifaa vya mitambo, vifaa vya matibabu, na vifaa vya elektroniki.

2. Wakati bolts za hexagonal zinatumiwa katika vifaa vya elektroniki, vifaa vya matibabu, na maeneo mengine, bolts za chuma cha pua za hexagonal huchaguliwa kwa ujumla kwa sababu rangi ya uso wa chuma cha pua ni nzuri zaidi na upinzani wa kutu ni bora zaidi, ambayo inaweza kuweka mashine nzuri kwa muda mrefu. Ikiwa ni vifaa vya mitambo na vibration kubwa, inashauriwa kuchagua bolts ya hexagonal yenye nguvu ya juu.

| Jina la Bidhaa | DIN933 Hex Bolt |

| Nyenzo | Chuma cha kaboni, Chuma cha pua |

| Uso Maliza | Zinki ya manjano, Nyeusi, Bluu na zinki nyeupe, Imepauka |

| Rangi | Njano, Nyeusi, Bluu Nyeupe, Nyeupe |

| Nambari ya Kawaida | DIN933 |

| Daraja | 4.8 5.8 8.8 10.9 A2-70 |

| Kipenyo | M2 M4 M5 M6 M7 M8 M10 M12 M14 M16 M18 M20 M45 M48 M52 |

| Fomu ya thread | Uzi mwembamba, Uzi mwembamba |

| Mahali pa asili | Hebei, Uchina |

| Chapa | Muyi |

| Pakiti | Sanduku+katoni+katoni+pallet |

| Bidhaa inaweza kubinafsishwa | |

| 1.Bolts za hexagonal hutumiwa sana ndani na nje. Maombi ya nje ni zaidi ya ujenzi wa mitambo, madaraja na barabara, na vifaa vya nguvu; maombi ya ndani zaidi ni ya vifaa vya mitambo, vifaa vya matibabu, na vifaa vya elektroniki. 2. Wakati bolts za hexagonal zinatumiwa katika vifaa vya elektroniki, vifaa vya matibabu, na maeneo mengine, bolts za chuma cha pua za hexagonal huchaguliwa kwa ujumla kwa sababu rangi ya uso wa chuma cha pua ni nzuri zaidi na upinzani wa kutu ni bora zaidi, ambayo inaweza kuweka mashine nzuri kwa muda mrefu. Ikiwa ni vifaa vya mitambo na vibration kubwa, inashauriwa kuchagua bolts ya hexagonal yenye nguvu ya juu. | |

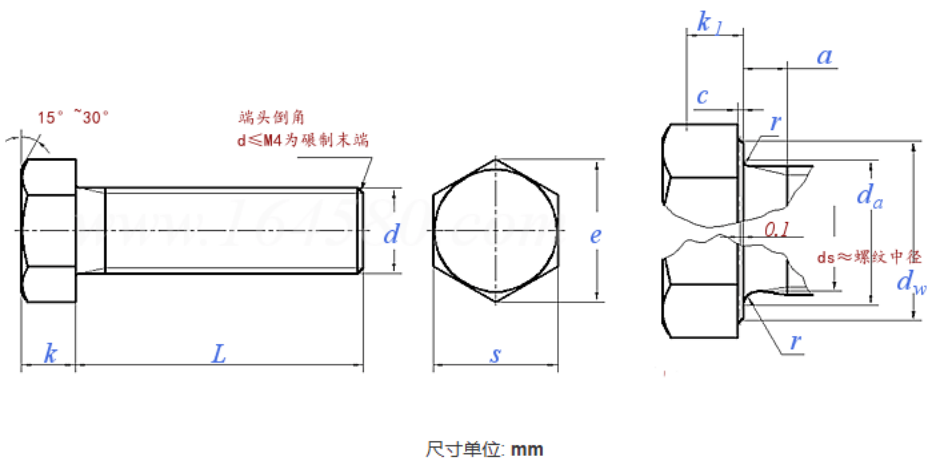

| Maalum ya Thread d | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | |||

| P | Uzi | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | ||

| a | max | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 3.75 | 4.5 | 5.25 | 6 | 6 | ||

| c | min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | ||

| max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | |||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | ||

| dw | A | min | 2.4 | 3.2 | 4.1 | 4.6 | 5.1 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | |

| B | min | / | / | / | / | / | 5.7 | 6.7 | 8.7 | 9.4 | 11.4 | 15.4 | 17.2 | 20.1 | 22 | ||

| e | A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | |

| B | min | / | / | / | / | / | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 18.72 | 20.88 | 23.91 | 26.17 | ||

| k | Jina | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | 8.8 | 10 | ||

| A | min | 0.98 | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | ||

| max | 1.22 | 1.52 | 1.82 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | |||

| B | min | / | / | / | / | / | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | 8.51 | 9.71 | ||

| max | / | / | / | / | / | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | 9.09 | 10.29 | |||

| k1 | min | 0.7 | 0.9 | 1.1 | 1.3 | 1.6 | 1.9 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | 5.96 | 6.8 | ||

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | ||

| s | max=nominella | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | ||

| A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | ||

| B | min | / | / | / | / | / | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 16.57 | 18.48 | 21.16 | 23.16 | ||

| Maalum ya Thread d | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | ||||

| P | Uzi | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | |||

| a | max | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | 13.5 | 15 | 15 | |||

| c | min | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |||

| max | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | ||||

| da | max | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | |||

| dw | A | min | 25.3 | 28.2 | 30 | 33.6 | / | / | / | / | / | / | / | / | / | ||

| B | min | 24.8 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.5 | 51.1 | 55.9 | 59.9 | 64.7 | 69.4 | 74.2 | |||

| e | A | min | 30.14 | 33.53 | 35.72 | 39.98 | / | / | / | / | / | / | / | / | / | ||

| B | min | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |||

| k | Jina | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | 28 | 30 | 33 | |||

| A | min | 11.28 | 12.28 | 13.78 | 14.78 | / | / | / | / | / | / | / | / | / | |||

| max | 11.72 | 12.72 | 14.22 | 15.22 | / | / | / | / | / | / | / | / | / | ||||

| B | min | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | |||

| max | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | ||||

| k1 | min | 7.8 | 8.5 | 9.6 | 10.3 | 11.7 | 12.8 | 14.4 | 15.5 | 17.2 | 17.9 | 19.3 | 20.9 | 22.8 | |||

| r | min | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | 1.2 | 1.6 | 1.6 | |||

| s | max=nominella | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | |||

| A | min | 26.67 | 29.67 | 31.61 | 35.38 | / | / | / | / | / | / | / | / | / | |||

| B | min | 26.15 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |||