1. Utengenezaji wa mitambo: Karanga nyembamba za kufunga pembe za pembetatu hutumiwa hasa kuunganisha na kurekebisha vipengele mbalimbali vya mitambo, kama vile screws, flanges, fani, na camshafts, ili kuhakikisha uendeshaji wa kawaida wa mashine.

2. Utengenezaji wa magari: Katika mchakato wa utengenezaji wa magari, kokwa nyembamba za kufuli za hexagonal hutumiwa kuunganisha na kulinda vipengee mbalimbali vya magari kama vile injini, ekseli, na kusimamishwa ili kuhakikisha usalama na uthabiti wa gari.

3. Sehemu ya ujenzi: Karanga nyembamba za kufunga za hexagonal hutumiwa sana katika mkusanyiko wa miundo ya chuma, kama vile madaraja, viwanda, nk. Ni nyepesi na zina sifa nzuri za kuzuia kulegea, ambazo zinaweza kuhakikisha uthabiti na usalama wa miundo ya chuma wakati wa matumizi.

4. Vifaa vya kielektroniki: Katika uwanja wa utengenezaji wa bidhaa za kielektroniki, kama vile simu za rununu, kompyuta, nk, karanga nyembamba za kufuli za hexagonal hutumiwa kurekebisha na kuunganisha vifaa anuwai, kama vile betri, ubao wa mama, maonyesho, nk, ili kuokoa nafasi na kupunguza uzito.

5. Mapambo ya nyumbani: Katika uwanja wa mapambo ya nyumbani, hexagonal locking karanga nyembamba hutumiwa kwa kawaida katika mkusanyiko wa samani, vinyago na bidhaa nyingine, ambazo haziwezi tu kuchukua jukumu la kurekebisha lakini pia kudumisha kuonekana safi.

6. Eneo la jumla: Karanga nyembamba za kufunga hexagonal pia hutumiwa sana katika mchakato wa uzalishaji na utengenezaji wa vifaa mbalimbali vya mitambo, vyombo, vifaa vya nyumbani, nk.

| Jina la Bidhaa | DIN985 Hex Lock Nut yenye bluu |

| Nyenzo | Chuma cha kaboni, Chuma cha pua |

| Uso Maliza | Zinki ya manjano, zinki nyeupe ya Bluu, rangi ya asili, zinki nyeupe, Decolourize, Dacromet |

| Rangi | Njano, Bluu Nyeupe, Nyeupe |

| Nambari ya Kawaida | DIN985 |

| Daraja | 4 8 10 A2-70 |

| Kipenyo | M4 M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 M33 M36 M39 M45 M48 |

| Fomu ya thread | Uzi mwembamba |

| Mahali pa asili | Hebei, Uchina |

| Chapa | Muyi |

| Pakiti | Sanduku+katoni+katoni+pallet |

| Bidhaa inaweza kubinafsishwa | |

| 1. Utengenezaji wa mitambo: Karanga nyembamba za kufunga pembe za pembetatu hutumiwa hasa kuunganisha na kurekebisha vipengele mbalimbali vya mitambo, kama vile screws, flanges, fani, na camshafts, ili kuhakikisha uendeshaji wa kawaida wa mashine. 2. Utengenezaji wa magari: Katika mchakato wa utengenezaji wa magari, kokwa nyembamba za kufuli za hexagonal hutumiwa kuunganisha na kulinda vipengee mbalimbali vya magari kama vile injini, ekseli, na kusimamishwa ili kuhakikisha usalama na uthabiti wa gari. 3. Sehemu ya ujenzi: Karanga nyembamba za kufunga za hexagonal hutumiwa sana katika mkusanyiko wa miundo ya chuma, kama vile madaraja, viwanda, nk. Ni nyepesi na zina sifa nzuri za kuzuia kulegea, ambazo zinaweza kuhakikisha uthabiti na usalama wa miundo ya chuma wakati wa matumizi. 4. Vifaa vya kielektroniki: Katika uwanja wa utengenezaji wa bidhaa za kielektroniki, kama vile simu za rununu, kompyuta, nk, karanga nyembamba za kufuli za hexagonal hutumiwa kurekebisha na kuunganisha vifaa anuwai, kama vile betri, ubao wa mama, maonyesho, nk, ili kuokoa nafasi na kupunguza uzito. 5. Mapambo ya nyumbani: Katika uwanja wa mapambo ya nyumbani, hexagonal locking karanga nyembamba hutumiwa kwa kawaida katika mkusanyiko wa samani, vinyago na bidhaa nyingine, ambazo haziwezi tu kuchukua jukumu la kurekebisha lakini pia kudumisha kuonekana safi. 6. Eneo la jumla: Karanga nyembamba za kufunga hexagonal pia hutumiwa sana katika mchakato wa uzalishaji na utengenezaji wa vifaa mbalimbali vya mitambo, vyombo, vifaa vya nyumbani, nk. | |

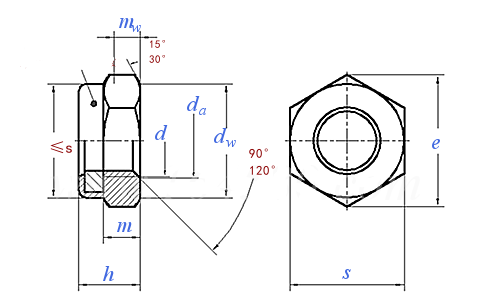

| Maalum ya Thread D | M3 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | ||

| P | kiongozi wa ndege | Uzi mwembamba | 0.5 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 |

| Uzi mwembamba1 | / | / | / | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | ||

| Uzi mwembamba2 | / | / | / | / | / | / | 1.25 | 1.25 | / | / | 1.5 | 1.5 | 1.5 | / | / | / | / | / | / | / | / | / | ||

| da | min | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | |

| max | 3.45 | 4.6 | 5.75 | 6.75 | 7.75 | 8.75 | 10.8 | 13 | 15.1 | 17.3 | 19.5 | 21.6 | 23.7 | 25.9 | 29.1 | 32.4 | 35.6 | 38.9 | 42.1 | 45.4 | 48.6 | 51.8 | ||

| dw | min | 4.6 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | 24.9 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.6 | 51.1 | 55.9 | 60.6 | 64.7 | 69.4 | |

| e | min | 6.01 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 72.09 | 76.95 | 82.6 | |

| h | max=nominella | 4 | 5 | 5 | 6 | 7.5 | 8 | 10 | 12 | 14 | 16 | 18.5 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | 45 | 48 | |

| min | 3.7 | 4.7 | 4.7 | 5.7 | 7.14 | 7.64 | 9.64 | 11.57 | 13.3 | 15.3 | 17.66 | 18.7 | 20.7 | 22.7 | 25.7 | 28.7 | 31.4 | 34.4 | 37.4 | 40.4 | 43.4 | 46.4 | ||

| m | min | 2.4 | 2.9 | 3.2 | 4 | 4.7 | 5.5 | 6.5 | 8 | 9.5 | 10.5 | 13 | 14 | 15 | 15 | 17 | 19 | 22 | 25 | 27 | 29 | 32 | 36 | |

| mw | min | 1.65 | 2.2 | 2.75 | 3.3 | 3.85 | 4.4 | 5.5 | 6.6 | 7.7 | 8.8 | 9.9 | 11 | 12.2 | 13.2 | 14.8 | 16.5 | 18.2 | 19.8 | 21.5 | 23.1 | 24.8 | 26.5 | |

| s | max=nominella | 5.5 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | |

| min | 5.32 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | 26.16 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.8 | 68.1 | 73.1 | ||

| 1000 pcs / uzito KG | 0.5 | 1 | 1.4 | 2.4 | 3 | 5.1 | 10.6 | 17.2 | 26 | 34 | 45 | 65 | 75 | 100 | 162 | 212 | 317 | 415 | 499 | 628 | 771 | 998 | ||