1.Washer ni muhuri unaojaza pengo kati ya nyuso mbili za kupandisha, kuruhusu vifaa viwili vya kazi kuunganishwa pamoja bila kuvuja hata wakati umebanwa.

2.Kiosha kinaweza kujaza kasoro fulani juu ya uso, ikiruhusu kutokamilika kwa sehemu za kupandisha za vifaa vya kazi. washer kwa ujumla hufanywa kwa kukata na kugawanya karatasi nyembamba.

3.Kwa ujumla, nyenzo bora ya washer ni ile inayoruhusu kiwango fulani cha deformation ili iweze kuharibika na kujaza nafasi inayolingana (ikiwa ni pamoja na makosa kidogo) wakati wa mkusanyiko. Baadhi ya washer zinahitaji kuongezwa kwa sealants moja kwa moja kwenye uso ili gasket kufanya kazi vizuri.

| Jina la Bidhaa | Washer wa gorofa |

| Nyenzo | Chuma cha kaboni, Chuma cha pua |

| Uso Maliza | Zinki ya manjano, Nyeusi, Bluu na zinki nyeupe, Imepauka |

| Rangi | Njano, Nyeusi, Bluu Nyeupe, Nyeupe |

| Nambari ya Kawaida | DIN,ASME,ASNI,ISO |

| Daraja | 4.8 5.8 8.8 10.9 A2-70 |

| Kipenyo | M1.6 M2 M4 M5 M6 M7 M8 M10 M12 M14 M16 M18 M20 M45 M48 M52 M56 M60 M64 |

| Fomu ya thread | Uzi mwembamba, Uzi mwembamba |

| Mahali pa asili | Hebei, Uchina |

| Chapa | Muyi |

| Pakiti | Sanduku+katoni+katoni+pallet |

| Bidhaa inaweza kubinafsishwa | |

| 1.Washer ni muhuri unaojaza pengo kati ya nyuso mbili za kupandisha, kuruhusu vifaa viwili vya kazi kuunganishwa pamoja bila kuvuja hata wakati umebanwa. 2.Kiosha kinaweza kujaza kasoro fulani juu ya uso, ikiruhusu kutokamilika kwa sehemu za kupandisha za vifaa vya kazi. washer kwa ujumla hufanywa kwa kukata na kugawanya karatasi nyembamba. 3.Kwa ujumla, nyenzo bora ya washer ni ile inayoruhusu kiwango fulani cha deformation ili iweze kuharibika na kujaza nafasi inayolingana (ikiwa ni pamoja na makosa kidogo) wakati wa mkusanyiko. Baadhi ya washer zinahitaji kuongezwa kwa sealants moja kwa moja kwenye uso ili gasket kufanya kazi vizuri. | |

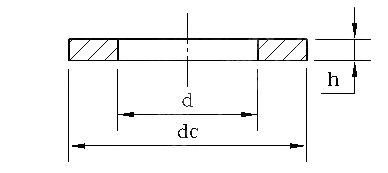

| Maalum ya Thread d | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | |||

| d | max | 1.84 | 2.34 | 2.84 | 3. 38 | 4.48 | 5.48 | 6.62 | 8.62 | 10.77 | 13.27 | 15. 27 | 17.27 | 19.38 | 21.33 | ||

| min | 1.7 | 2.2 | 2.7 | 3.2 | 4.3 | 5.3 | 6.4 | 8.4 | 10.5 | 13 | 15 | 17 | 19 | 21 | |||

| dc | max | 4 | 5 | 6 | 7 | 9 | 10 | 12 | 16 | 20 | 24 | 28 | 30 | 34 | 37 | ||

| min | 3.7 | 4.7 | 5.7 | 6.64 | 8.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 27.48 | 29.48 | 33.38 | 36.38 | |||

| h | Jina | 0.3 | 0.3 | 0.5 | 0.5 | 0.8 | 1 | 1.6 | 1.6 | 2 | 2.5 | 2.5 | 3 | 3 | 3 | ||

| max | 0.35 | 0.35 | 0.55 | 0.55 | 0.9 | 1.1 | 1.8 | 1.8 | 2.2 | 2.7 | 2.7 | 3.3 | 3.3 | 3.3 | |||

| min | 0.25 | 0.25 | 0.45 | 0.45 | 0.7 | 0.9 | 1.4 | 1.4 | 1.8 | 2.3 | 2.3 | 2.7 | 2.7 | 2.7 | |||

| Maalum ya Thread d | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |||

| d | max | 23.33 | 25.33 | 28.33 | 31.39 | 34.62 | 37.62 | 42.62 | 45.62 | 48.62 | 52.74 | 56.74 | 62.74 | 66.74 | 70.74 | ||

| min | 23 | 25 | 28 | 31 | 34 | 37 | 42 | 45 | 48 | 52 | 56 | 62 | 66 | 70 | |||

| dc | max | 39 | 44 | 50 | 56 | 60 | 66 | 72 | 78 | 85 | 92 | 98 | 105 | 110 | 115 | ||

| min | 38.38 | 43.38 | 49.38 | 55.26 | 58.8 | 64.8 | 70.8 | 76.8 | 83.6 | 90.6 | 96.6 | 103.6 | 108.6 | 113.6 | |||

| h | Jina | 3 | 4 | 4 | 4 | 5 | 5 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | ||

| max | 3.3 | 4.3 | 4.3 | 4.3 | 5.6 | 5.6 | 6.6 | 9 | 9 | 9 | 9 | 11 | 11 | 11 | |||

| min | 2.7 | 3.7 | 3.7 | 3.7 | 4.4 | 4.4 | 5.4 | 7 | 7 | 7 | 7 | 9 | 9 | 9 | |||